Collections

Collections The Legend of Silk and Wood: A Hong Kong Qin Story

The Legend of Silk and Wood: A Hong Kong Qin Story Art of Silk and Wood

Art of Silk and Wood Qin Making Procedure

Qin Making Procedure Sanding

Sanding

-

Step 7: Sanding

The sanding is to be completed with abrasive paper of different grit sizes, chosen according to the class number of the antler powder applied. Both dry and wet sanding have to be performed. For the coarse and thin bottom layer of base cement, use rough abrasive paper or coarse stones for sanding. The successive medium-fine cement layers are to be sanded with wet abrasive paper of a comparable fineness. The upper most fine base cement layer should be sanded with a finer waterproof abrasive paper. The process is to be completed until the top board of the qin is evenly flattened and smoothened.

-

Step 7: Sanding

Tools

- Wood block for sanding – to be wrapped with abrasive paper for use in sanding base cement

- Waterproof abrasive paper – a low-grit abrasive paper is used for sanding the bottom layer of base cement; a high-grit abrasive paper is used for sanding the top layer of fine base cement.

- Ruler – to regularly inspect whether the base cement layer has been sanded into a smooth and flat state

-

Step 7: Sanding

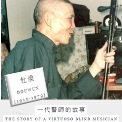

A qin body with an already gently sanded base cement

Maker: Chuen-wai, Choi Chang-sau’s daughter (apprenticeship began in 2012)

Maker’s note: This is a semi-finished qin jointly made by my father and me. It was the first time I experienced the joy of qin making. I was very impressed with the depth of knowledge and skills involved in the making of the seemingly simple qin. This is how I have come to understand my father’s lifelong passion for the art of qin making.