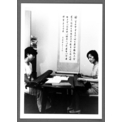

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date of Death | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

The sixth step of qin making process: cement priming

After completing the wood base, a horn spatula is used for priming the lacquer cement, which is made by mixing raw lacquer and antler powder. Antler powder is ground from broiled antler and categorised into the following grade classes: 800, 1200, 2000, etc. The greater the number is, the finer the powder. Multiple layers of lacquer cement have to be applied onto the qin base, beginning with the coarsest one. After the base cement has dried, it can be sanded smooth. The process is repeated a few times, using finer cement on each successive layer of application. After the lacquer cement has completely dried, it forms the base cement, which has a hard texture designed to protect the wood. An appropriate thickness of base cement can also improve the instrument’s timbre. The dried base cement has a natural chestnut brown hue which becomes black when mixed with carbon black, or sharp red or brownish red when mixed with cinnabar. Scraps of gemstones and coral, called the babaohui (eight-jewel powder), can also be added to create special visual effects. This photo shows the sixth step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| Material Type | Image |

| People | Choi Chang-sau |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0116 |

Copyright © 2012 Hong Kong Memory