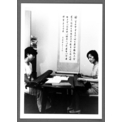

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date of Death | 2013 |

| People | Choi Chang-sau |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| Material Type | Image |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

The first step of qin making process: seeking

Selection of materials is of the utmost importance in the process of qin making. The material has to be particularly “light, porous, crisp, and smooth”. Naturally air-dried old Chinese fir, Chinese parasol and Chinese catalpa, that have been stored for years are the best materials for making a qin. On top of possessing good sound qualities, naturally air-dried wood seldom cracks. The top board of the qin is usually made of Chinese fir or Chinese parasol; the bottom board is usually made of Chinese catalpa or other hardwood. The wood for making the qin should have smooth grain lines and even width. There should be no knots or moth damage to the wood. This photo shows the first step of qin making process which was demonstrated by Choi Chang-sau.

| Date | 2013 |

| Material Type | Image |

| People | Choi Chang-sau |

| Collection | The Legend of Silk and Wood: A Hong Kong Qin Story |

| Source | Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Repository | Intangible Cultural Heritage Office |

| Note to Copyright | Permission for use in Hong Kong Memory is given by Intangible Cultural Heritage Office and Hong Kong Heritage Museum |

| Accession No. | lcs-hkqs-0096 |

Copyright © 2012 Hong Kong Memory